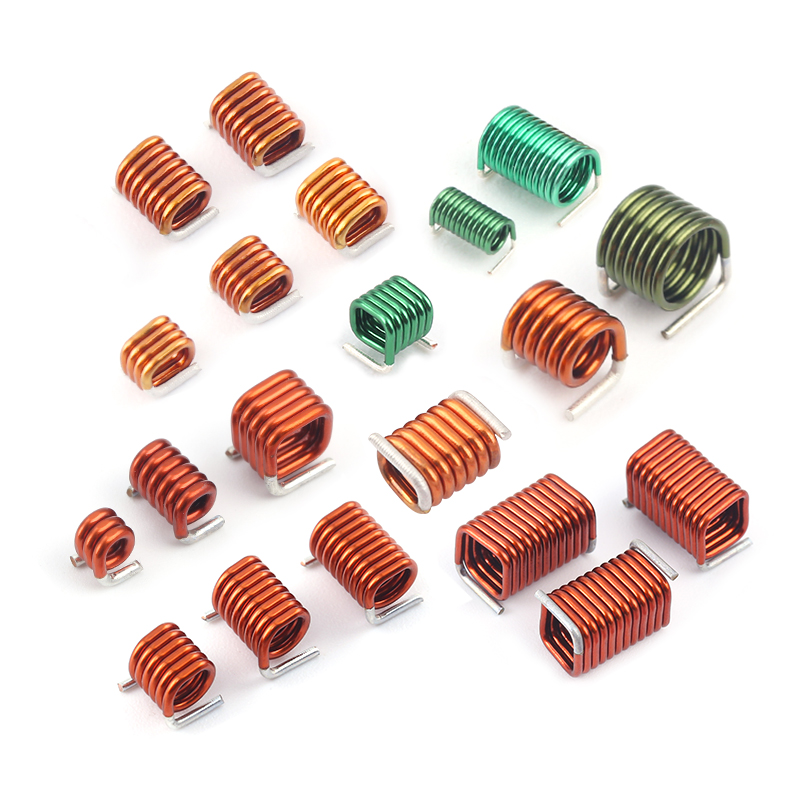

The supply chain distribution of air core inductor coils around the world plays a major role in ensuring efficient and effective delivery of these essential components to various industries.

Air core inductor coils are widely used in electronic equipment, telecommunications, and automotive applications, and their availability and timely delivery are crucial for the smooth operation of these industries. In recent news, the demand for air core inductor coils has been on the rise, and the supply chain distribution has become increasingly important to meet the growing needs of manufacturers and end-users.

The production and distribution of air core inductor coils involve a complex supply chain that spans across the globe. The process begins with the manufacturing of the inductor coils, which involves the use of high-quality materials and precision engineering to ensure optimal performance. Once the inductor coils are produced, they are then distributed through a network of suppliers, distributors, and retailers to reach end-users in various industries. This supply chain distribution is crucial for ensuring that the inductor coils are available in the right quantities and at the right time to meet the demands of the market.

Major manufacturers of air core inductor coils are located around the world, with production facilities in countries like China, Japan, Germany, and the United States. These manufacturers play a key role in the supply chain distribution of inductor coils, as they are responsible for producing and supplying these essential components to the global market. In recent years, the demand for air core inductor coils has been driven by the rapid advancements in technology, particularly in the fields of telecommunications, automotive electronics, and renewable energy systems, leading to an increased focus on efficient supply chain distribution to meet the growing needs of the industry.

In response to the growing demand for air core inductor coils, major manufacturers and distributors have been expanding their production and distribution capabilities to ensure a steady supply of these components to the market. This includes investment in advanced manufacturing technologies, logistical infrastructure, and supply chain management systems to improve the efficiency and flexibility of the distribution process. These efforts are aimed at meeting the diverse needs of industries across the globe and ensuring that air core inductor coils are available in the right specifications, quantities, and lead times.

The supply chain distribution of air core inductor coils also involves a complex network of suppliers, distributors, and logistical partners who play a critical role in the efficient delivery of these components to end-users. This includes the transportation of inductor coils from manufacturing facilities to distribution centers, and then to retailers and end-users around the world. The coordination and collaboration among these partners are essential for ensuring that air core inductor coils are available at the right place and time, and in good condition to meet the needs of industries requiring these essential components.

In conclusion, the supply chain distribution of air core inductor coils around the world is a major factor in meeting the growing demand for these essential components in various industries. It involves a complex network of manufacturers, suppliers, distributors, and logistical partners who work together to ensure the efficient production, distribution, and delivery of inductor coils to end-users in different parts of the world. As the demand for air core inductor coils continues to rise, the supply chain distribution will play an increasingly important role in meeting the needs of industries and supporting technological advancements across the globe.